What does it mean and why should you pay attention to it? Here we would like to give you an overview of the regulations and what they mean.

CERTIFICATION OF PERSONAL PROTECTIVE EQUIPMENT

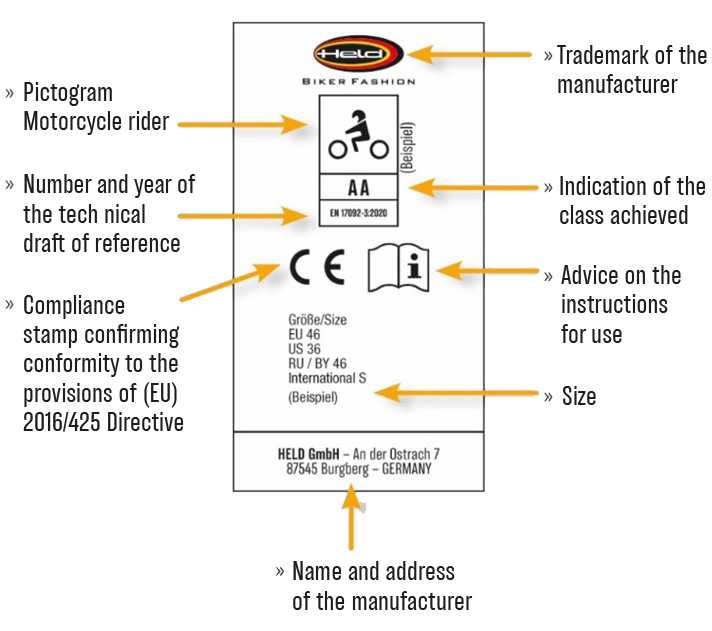

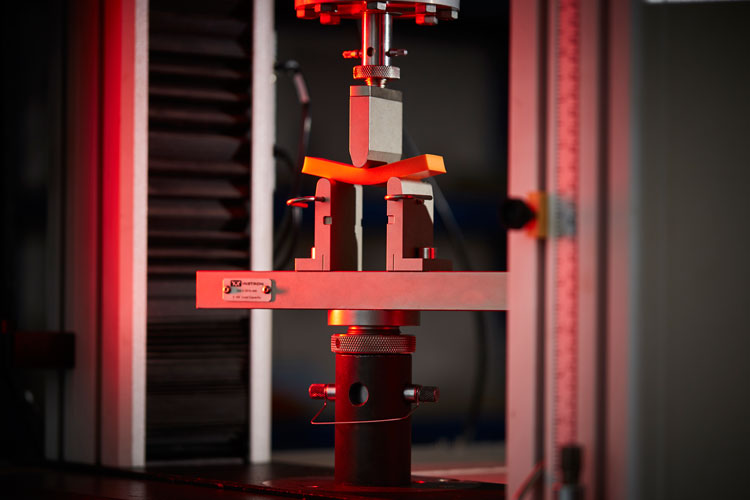

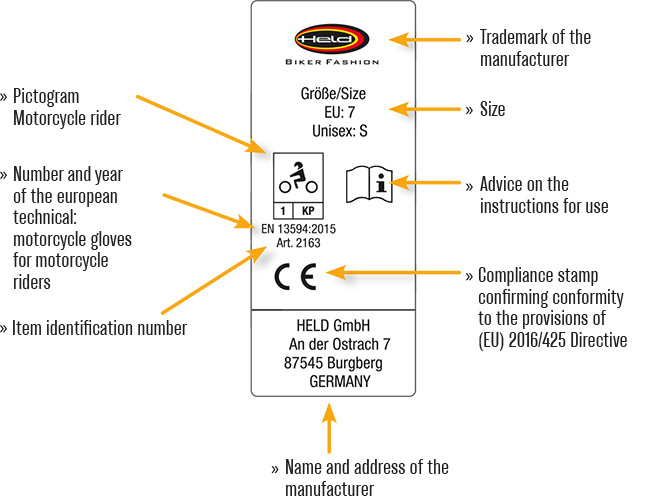

According to Regulation (EU) 2016/425, motorbike protective clothing falls under “Personal Protective Equipment” (PPE) and is tested and certified according to the respective EN standards by an accredited testing institute

If a product from a certain category passes the test procedures of an accredited testing institute, the standard is considered to be fulfilled and the product is considered to be safe for this particular application. This is the prerequisite for the product to be awarded the CE mark (European conformity). Within the standards, a distinction is made between different protection classes, whereby the general rule is: the higher the level/class, the better the protection.

The following standards are relevant in the certification of personal protective equipment for motorcyclists:

- EN 1150:1999 – High-visibility warning clothing for non-professional use.

- EN 20471:2013 – Standard for high-visibility warning clothing

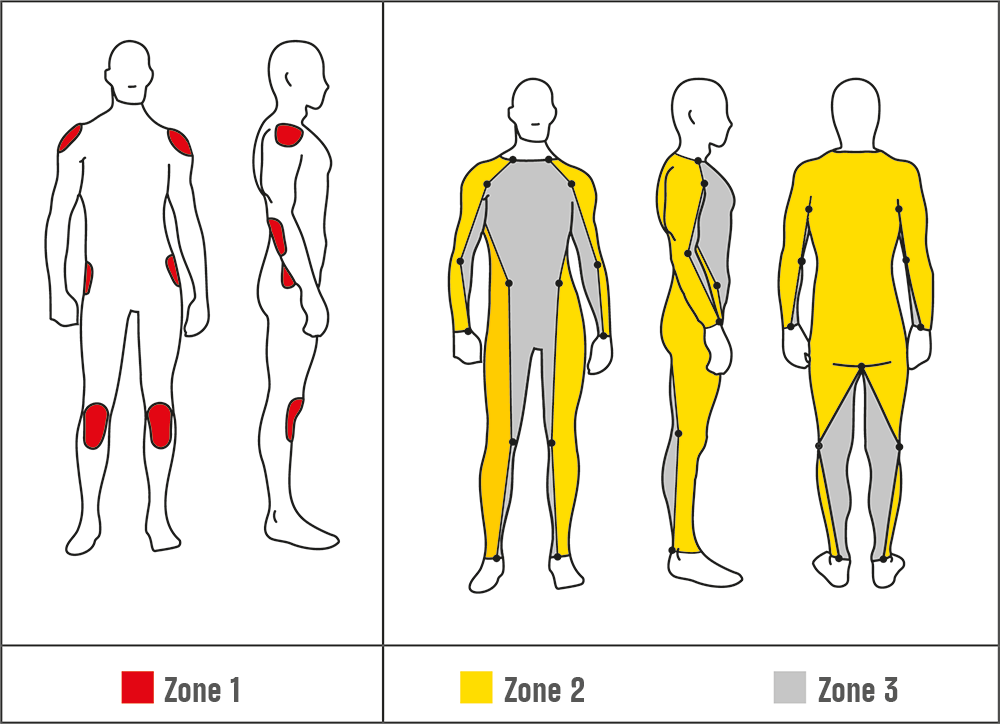

- EN 17092:2020 – Standard for motorcycle protective clothing

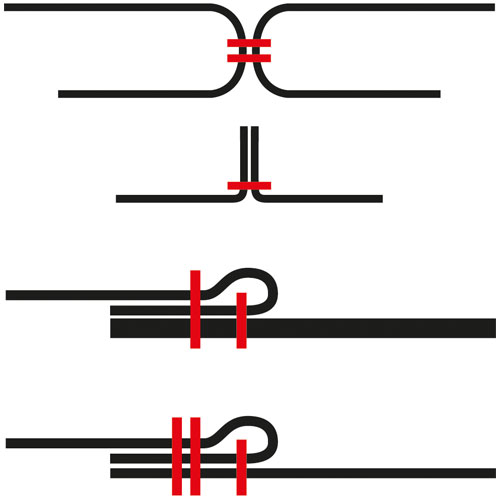

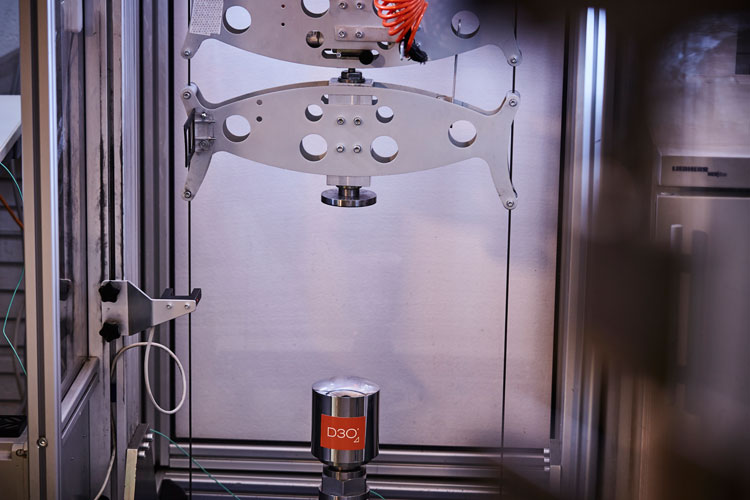

- EN 1621-1:2012 –Standard for articulated protectors

- EN 1621-2:2014 – Standard for back protectors

- EN 13594:2015 – Standard for motorcycle gloves

- ECE 22.05 – Standard for motorcycle helmets

- EN 13634:2017 – Standard for protective footwear for motorcyclists when riding motorcycles on and off road

Example of marking according to EN 17092:2020